2-axis Quadcopter Gimbal (Senior Design)

Team members: Sam Bright, Kevin Callaghan, Brendan Dowling, Jake Fitzpatrick, and Arthur Suchodola

Project Introduction

The scope of this project was to create a flight control system that can be integrated into a future vertical takeoff and landing (VTOL) fixed-wing aircraft. The design chosen to accomplish this goal was a servo-powered gimbal mechanism that allows the motors and propellers to rotate independently from the rest of the aircraft with 2 degrees of freedom (DOF). By utilizing two orthogonal servo motors, the system allows the motor’s thrust to be pointed in any orientation, only limited by the range of motion of the servos used.

Besides being used in a VTOL aircraft, we wanted to make the design as versatile as possible; one major application for this design is in the aerial photography industry, which is a rapidly expanding market. Traditionally, a quadcopter or hexacopter (6 propeller aircraft) with fixed motors is used for aerial photography applications. In order to get stabilized video footage from this platform, the camera has to be mounted under the aircraft with a bulky gimbal stabilization system and the pilot’s first-person view (FPV) camera used to navigate the aircraft is usually mounted separately on the front of the aircraft, fixed to the frame. The two major disadvantages of this configuration are that the cameras are pointing in different directions and are difficult to control, with one pilot as well as the potential for the FPV camera to have visual artifacts/noise from the motor vibrations.

Our design solves both of these issues by allowing the motor gimbals to take care of in-flight stabilization, keeping the body of the aircraft level at all times, independent of what flight maneuvers the aircraft is performing. This allows the main recording camera to be mounted side by side with the FPV camera, which makes one-pilot flying much more simple. Other potential applications for this design could be in search and rescue operations where it can cover much more ground than a traditional quadcopter, thanks to the speed and efficiency advantages of fixed-wing flight, while still being able to seamlessly transition into vertical flight “quadcopter mode” for more precise maneuvering and hovering.

Design considerations

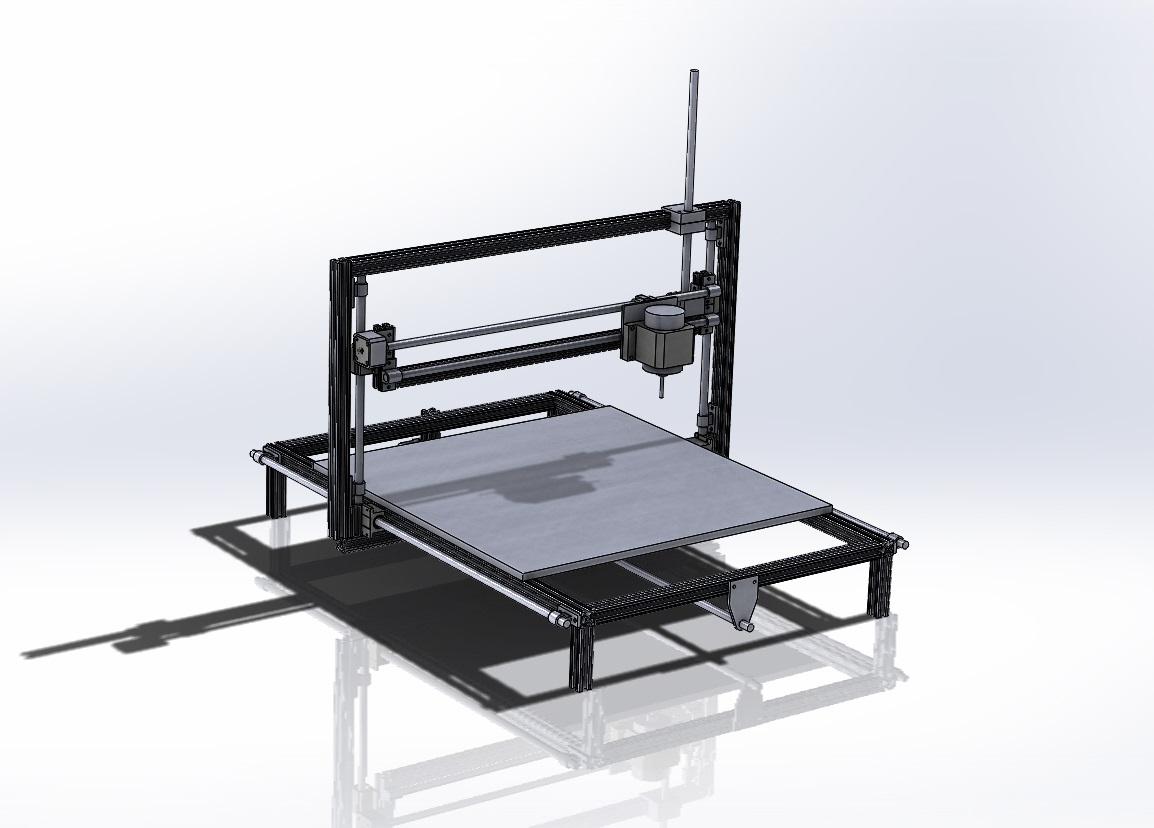

In order to be viable in any aerospace application, the gimbal mechanism must remain relatively compact and light compared to a traditional fixed-motor solution to make the added functionality worth the additional weight and size penalty. Several iterations of ring and gimbal designs were explored to reduce the overall weight and outer diameter of the mechanism. Ducted propellers were proposed as a way to potentially gain more thrust output and several designs were tested with SolidWorks Simulations.

After the best performing duct was selected and 3D printed, the final two candidate designs (a ducted and non-ducted propeller) were tested on a thrust stand to compare real-world performance. The results from all design analyses were compiled into a decision matrix to help guide which design to pursue.

In the table below, the ratio of the usable surface area is comparing how large the diameter of the gimbal is compared to the diameter of the propeller. The normalized manufacturing time is the amount of time needed to 3D print the components for each design. Due to the large increase in both the size and manufacturing time of the ducted design, the non-ducted design was chosen.

Final design

The use of a non-ducted propeller allowed for a critical design modification: instead of the inner gimbal ring being the large duct around the propeller, we could make the motor mount fixed to a rod for rotation in one direction. This allows the overall size of the mechanism to be reduced which saves weight and reduces packaging constraints when integrating into an airframe. It is worth noting that the outermost ring is for the prototype gimbal test stand and would not be required in the final airframe integration; the outer servo motor and pivot point opposite the motor can be integrated directly into the frame.

The motor is mounted via press-fit between a 3d printed motor mount and a carbon fiber rod that acts as one axis of rotation. The carbon fiber rod is driven by a servo motor via a shaft coupler and is supported on the other end by a nylon sleeve bearing to reduce rotational friction. The wiring for the motor is routed along the carbon fiber rod and into a cable routing channel on the inside of the inner ring. Since the inner ring needs to be able to rotate independently from the outer ring, there is a hollow carbon fiber shaft connecting the inner and outer rings that allow the cables to be passed through without risk of pinching or binding. As with the first rotational axis, there is another nylon sleeve bearing on the outside of this hollow CF shaft.

Manufacturing

To keep the project on budget and on schedule, off the shelf parts were used whenever possible. Due to the unique design of the gimbal, 3D printing was used to make the gimbal rings and motor mount. Nylon was selected as a print material due to its strength, durability, impact resistance, and lower than average density. Unfortunately, due to classes being moved online due to COVID-19, access to the labs at Rutgers was closed. Since I have my own 3D printer we were able to complete the project remotely, but were forced to use ABS as my printer is not well equipped to print Nylon. Despite having lower strength than Nylon, ABS is still a good choice for this application due to its durability and impact resistance.

You’ll notice that the printed part shown below doesn’t match the original design of the gimbal ring. The other restriction of using my 3d printer rather than the industrial-grade printers available at Rutgers is that the maximum print size is smaller and, in this case, too small for the ring to fit. The solution for this problem was to print the ring in two halves and connect it with a dovetail joint – something that i’ve used a couple times before with good success. The trick with this method is knowing your printer and knowing your print material, since the material will expand when being extruded and shrink when cooling. For ABS I modified the model to have a 0.5 mm gap between the connecting dove tails and it resulted in a correct, but snug, fit that didn’t require any additional adhesive.

Concurrently with the design and manufacturing of the gimbal mechanism, I developed a wiring schematic for a 4-gimbal mechanism plane system and tested the components with each other. All of the logic runs through the Navio 2 flight controller, which is a Raspberry Pi based device that allows for custom programming and complete control of the system; this is required due to the needs to control 8 servo motors independently. The brushless motors (for propelling the aircraft) and servo motors are both controlled via Pulse Width Modulation (PWM) outputs from the Navio 2. Since there are not enough native PWM outputs on the Navio 2, we purchased a USB PWM controller that provides 4 expansion channels. Other notable power components include:

- Power Distribution Board (PDB) – connects directly to the battery and distributes power to all of the power system components as well as providing 12V and 5V outputs.

- Electronic Speed Controller (ESC) – As the name suggests, it controls the motor speed by receiving input commands from the flight controller PWM output and converting a DC input to 3-phase AC for the brushless motor.

- Buck converters (Step down converter) – The system utilizes two buck converters to reduce higher voltage to 5V. One is to power the 8 digital servo motors, since each requires ~2A and this is well out of spec from what the Navio 2 can supply. The other steps down the 12V PDB output to 5V to help power the Navio 2. This is required because the Navio 2 maximum input current is ~2A and the 5V output from the PDB can only supply 1.5A.

- Input Capacitor -The high current draw of the system (~100-120A at/near full throttle) coupled with the constantly changing current draw from different throttle speeds causes what’s known as voltage “sag”, or fluctuation in voltage supplied by the battery dependent on power draw. This can be fixed by adding a capacitor across the main battery leads; the capacitor charges and discharges as voltage changes and acts as a buffer to smooth out fluctuations.

Software

Due to the unique needs of the gimbal actuation and controls schemes, all of the gimbal servo related controls were built from the ground up for this project. Because we wanted to make the user interface as close to a traditional quadcopter as possible, we created control-mapping diagrams for all axes of flight maneuvers and individually programmed the servos to autonomously react to transmitter stick inputs. Essentially what the code does is rather than tilt/rotate the aircraft by adjusting individual motor speeds it adjusts the position of the 8 servos. The end result is indistinguishable from the user’s perspective, but provides all of the flight advantages of the gimbal systems.

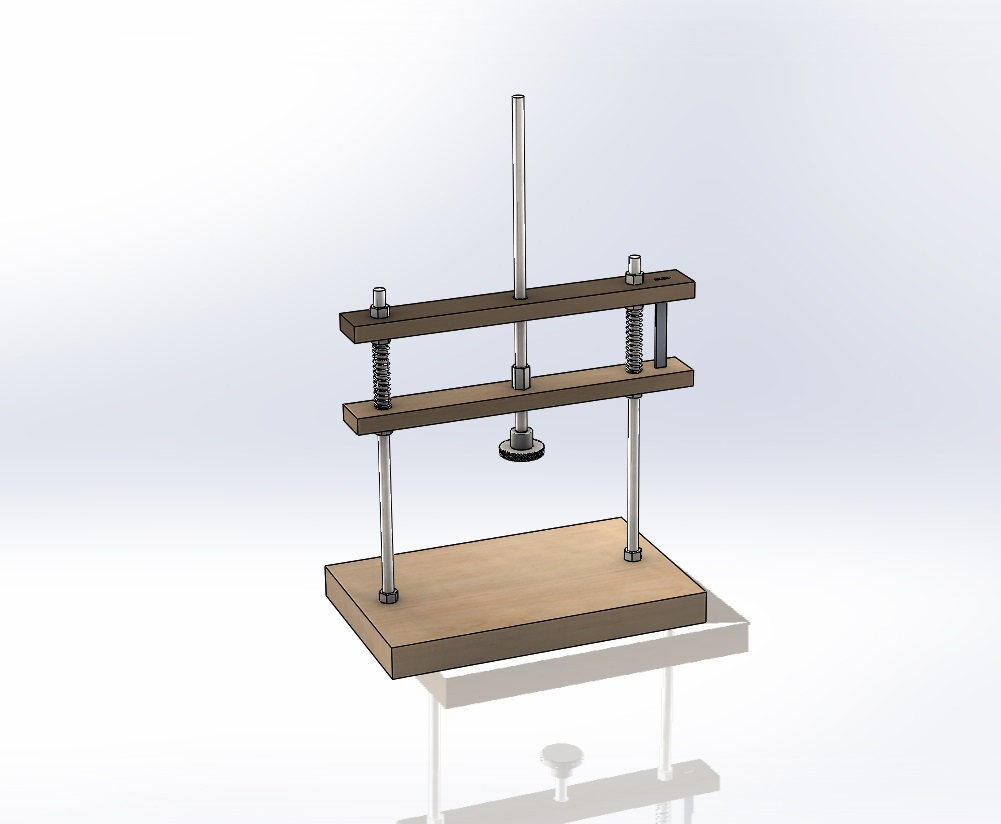

Gimbal test stand

The final result of this project was to build a test stand that would demonstrate the articulation abilities of the gimbal mechanism and how it responded to onboard flight controller data as well as combined auto stabilization and RC inputs. Notice how the magnitude of servo movement is constant and independent of what the auto stabilization controls are doing to keep the propeller pointed upwards. This is important because, as mentioned in the software discussion above, it maintains a predictable system response to user inputs from the RC transmitter. The test stand integrates a power supply, navio 2 flight controller, and the gimbal mechanism.

Other Projects

- All

- advanced manufacturing

- quadcopters

- solidworks/cad