Cheese Press

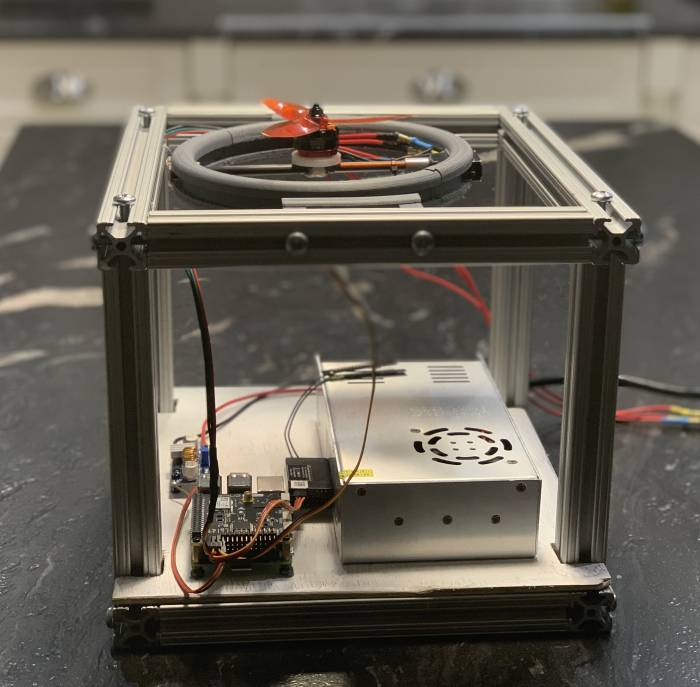

One of my hobbies outside of the technical sphere is cooking and, in particular, I enjoy cultivating my own produce and herbs at home. Since one of my favorite foods is cheese, both to cook with and enjoy on its own, I wanted to extend this principle to some of the cheese I use (and learn a thing or two in the process). A cheese press is used for mechanically removing excess liquid (whey) from the cheese before the forming and aging process can occur. A quick google search for a cheese press will yield two main types of press: the dutch style which uses counterweights/ bulky swing arms and a design which this is inspired by, but requires weights to be put on top of the press to hold it down. The other drawback of both of these designs is that commercially available models cost several hundred dollars. My criteria for this cheese press is it had to be compact, provide feedback on how much pressure was being applied to the cheese, be able to accommodate large wheels of cheese up to 12” in diameter, and cost less than $100 to build.

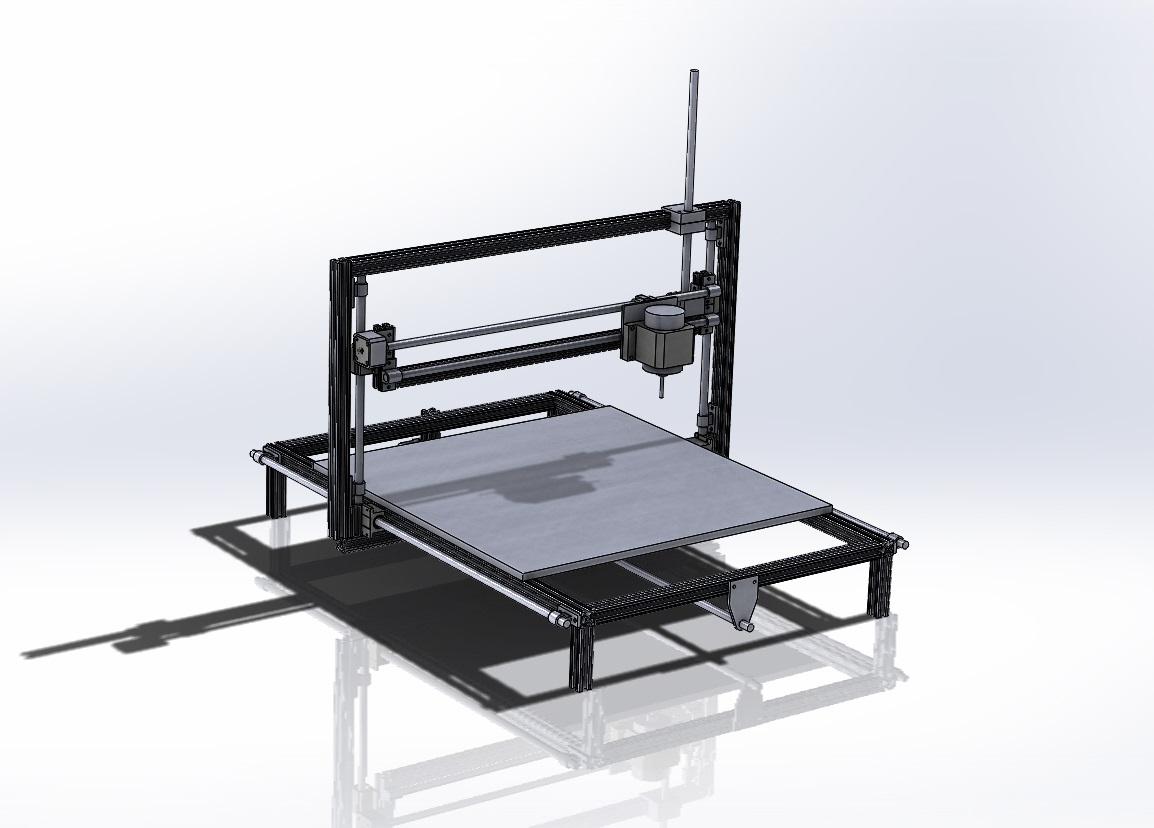

The design of this press utilizes a wood base attached to two threaded rods, two wood plates, and two compression springs separating the two wood plates. The upper plate is fixed in place by hex nuts above and below; this provides a surface for the springs to compress against to create force on the cheese. Additionally, there is a through-hole with a nylon sleeve bearing to allow the lead screw to pass through the upper plate without friction. The lower plate is supported by hex nuts below but is free to move upward and compress the springs. Attached to the lower plate is the force gauge which is free to slide through the slot in the upper plate to display how much force is being applied to the cheese.

The center acme lead screw and handle are the driving force of the press. As the force knob is lowered down to contact the cheese form the only moving part is the lead screw inside the acme nut, since there is nothing contacting the force knob and therefore no upward force generated. As the knob contacts the top of the cheese form, the force is transmitted through the lead screw into the lower plate, compressing the springs. Using the spring constants (how much force required to compress the spring by 1″) and some simple math to account for the two springs bearing equal load, we can calibrate the force gauge to accurately represent the force applied to the cheese.

The engineering drawing above shows an exploded view of the cheese press assembly and the costing bill of materials (BOM). All parts besides the wood can be sourced from industrial supplier McMaster-Carr who are known for high quality, tight tolerance products. A few of these parts, such as the hex nuts and washers, could be purchased from a home improvement or hardware store in smaller quantities and lower overall cost. The total price of the press, again excluding the wood, is ~$77; with the cost of sales tax and wood factored in, the total cost should be just under the $100 threshold.

Other Projects

- All

- advanced manufacturing

- quadcopters

- solidworks/cad