Nathan Reetz

Mechanical Engineer

About Me

Hello! I’m Nathan, a mechanical engineer based in Hamilton, NJ.

I enjoy working on challenging and engaging projects, whether it’s on the job with a team of engineers or at home on my projects. I’m driven to always be experiencing new things and to grow my knowledge along the way.

I graduated from Rutgers University-New Brunswick with a B.S. in Mechanical Engineering in 2020. Concurrently with my studies, I worked as an R&D Technology intern at Veeco Instruments. Since graduating, I have continued to work as a Mechanical Engineer for the New Product Development (NPD) team at Veeco.

When I am not working on one of my projects I enjoy spending time hiking, cycling, and playing the piano.

Experience

Veeco Instruments

Mechanical Engineer II

September 2020 – Present

(Promoted February 2022)

- Designed components and sub-assemblies of an MOCVD compound semiconductor system

- Contributed to the New Product Development (NPD) engineering team on semiconductor manufacturing equipment

- Ultra High Vacuum and High Temperature operating conditions in a production environment

- Led R&D projects for next-gen PiezoCon sensors from design to prototyping/testing phase

- Responsible for assembly design, custom part sourcing, and laboratory performance testing

- Developed CFD models that allow for fast, precise, and optimized solutions for customer-specific applications

- Unlocked previously inaccessible markets/customers by utilizing CFD models to tune our system to the customer’s operating conditions and target parameters

- Before the CFD models were implemented, customer application calculations were long lead-time tasks that gave approximate performance rather than targeted results

- Experience with semiconductor manufacturing equipment in a cleanroom environment

Veeco Instruments

R&D Engineer Intern

May 2019 – September 2020

- Assisted in the design and construction of MOCVD compound semiconductor equipment

- Followed iterative design processes to identify and develop solutions for system vulnerabilities

- Developed and analyzed thermal, flow, and FEA simulations at component and system level used to redesign components and subassemblies which led to an increase in system reliability and performance by 150%

- Designed components and subassemblies for several large scale R&D projects

- Created technical drawings and performed stacked tolerance analysis for components and assemblies

- Engineered custom component solutions to satisfy packaging and performance requirements

- Responsible for R&D testing, data collection, and troubleshooting of mechanical systems

- Extensive experience working in class 10 & 100 cleanrooms

- Utilized knowledge of MATLAB and signals processing to filter and analyze system measurement data

- Assisted the project management team with supply chain and procurement

- Drove BOMs and Purchase Reqs for R&D parts

- Worked directly with vendors to procure custom components

- Contributed to a rapid response engineering tiger team

- Made proposals for machine calibration techniques that allowed an offline reactor to resume production

- Conducted lab testing for design verification and repeatability

Rutgers University-New Brunswick May 2017 – May 2020

Major: Mechanical Engineering

GPA: 3.17 Honors: Dean’s List Fall 2019

Notable coursework

- Mechatronics (Arduino, MATLAB, & Simulink)

- System Dynamics & Controls

- Multiphysics Simulations (MATLAB & ANSYS)

- Mechanical Engineering Computational Analysis (MATLAB)

- Design of Mechanical Components

- Design of Mechanisms

Arizona State University August 2015 – May 2017

Major: Mechanical Engineering

GPA: 3.39 Honors: Dean’s List Fall 2017

Notable coursework

- Programming in C++

- Design Awareness

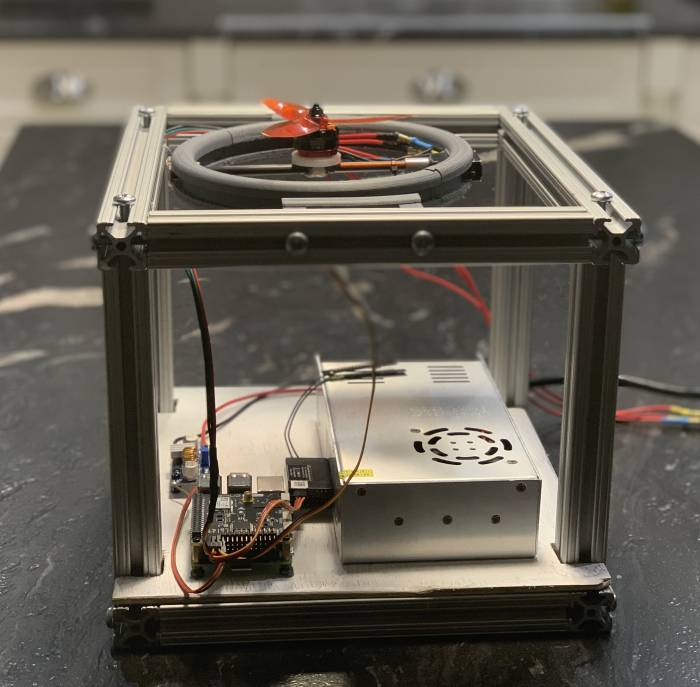

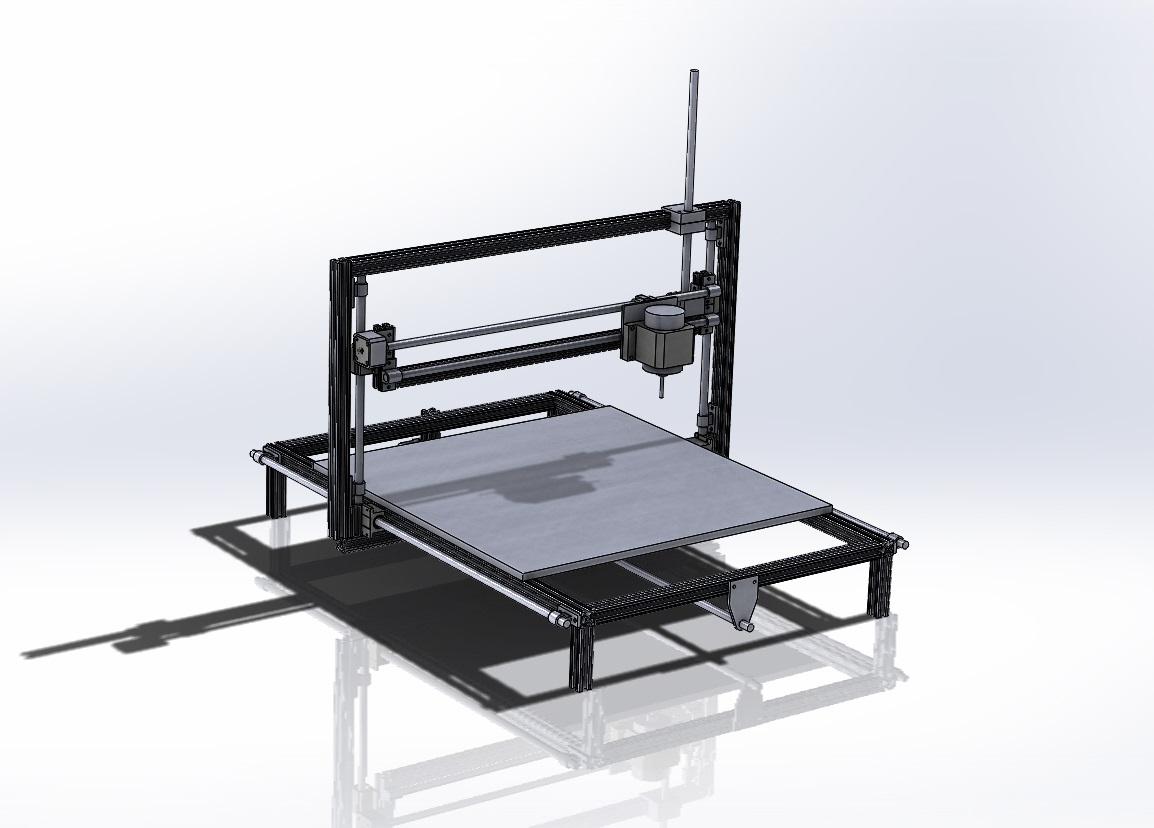

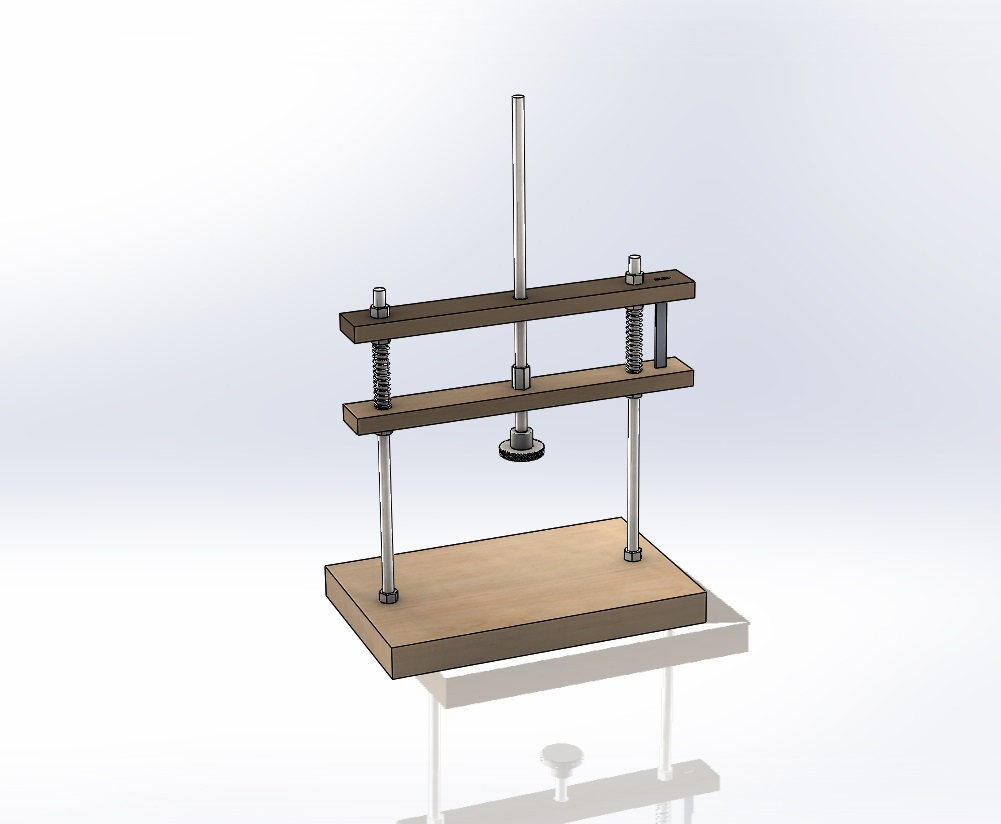

Projects

- All

- advanced manufacturing

- quadcopters

- solidworks/cad